Page 1 of 1

gettin it started : G200W

Posted: 17 Jan 2007, 21:07

by G200-GEM

i just purchased a G200w engine and gearbox.

its all wired up running a DELCO computer and camira loom setup to run on the twin cam. it came out of the car runnin but has not been run in a few months.

SO heres the issue. every sensor is working ive checked with a multimeter at the computer plug, and its getting fuel and spark. im using a VL fuel pump and a 2.5bar pressure regulator.

the pressure regulator would not pass any fuel through it whether it had vacuum or not, so i took it out of the system to try and start it, just to see if that was the issue.

so now it starts (not smoothly or easily but after a few turns) and it runs for a few seconds then cuts out...

i dont know if not having a regulator would be affecting it i know that the injector spray would be messed up as a result of not having the regulator, but i was of the impresion that the car would run okay anyway.

any suggestions?

thanks!

chris

Re: gettin it started : G200W

Posted: 18 Jan 2007, 00:10

by Poida

First thought is the pressure regulator might be incorrectly set up. Think about how it's plumbed up. It's job is to bleed off fuel once the ruel rail gets to the prescribed pressure.

So, how is it all plumbed now then? Do you have a fuel return line or is it just feeding full pump pressure to the injectors with no return line to the tank at all? That might cause the injectors to leak dribbles of fuel in drop form between their proper firing openings as well as a distorted spray pattern if the line pressure is too high.

I'd start by testing the flow rate and the operating pressure of the fuel pump first. If the pump appears to be right, then I'd check that the regulator is not jammed shut. Are you 100% sure you have the pressure regulator correctly installed?

I'm guessing that you have the G200W fuel rail and injectors with the 2 litre JE Camira EFI setup is that correct? Can you tell me exactly what components (everything including the sensors and the actuators) you have there? What throttle body and TPS are you using, the original ones or something from a different setup?

The engine should start but unless you duplicate all the items that the Camira ECU program was expecting (assuming the MemCal chip is the OEM Camira one too) then it won't quite run the way it should and it might not even allow the management system to operate fully if it finds components missing or not in the range that expects them to be in. Like the TPS for instance. Different EFI systems run different types of TPS. Some use a variable resistor (can be high impedence at either end depending on the system) and some use a switch with set points. That's just the TPS. What about the idle stepping system? Has the engine still got the same idle air setup so the computer can adjust the idle speed? It goes on... The engine management is only going to run it properly if the setup is what it expects to see.

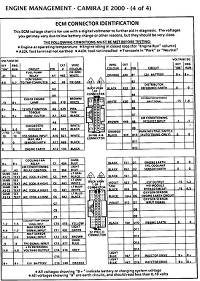

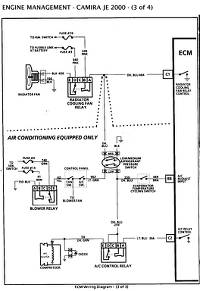

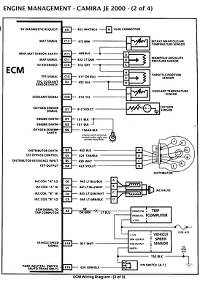

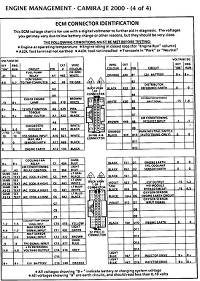

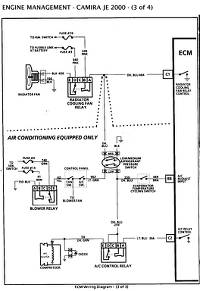

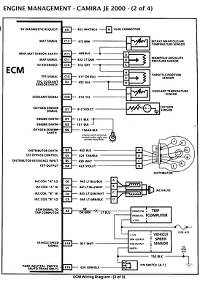

You can use these images from the JE Camira factory workshop manual to check that you have all the same components hooked up to start with. Even then you still need to be sure they are calibrated the same as the Camira components were if any are non original Camira pieces.

Posted: 18 Jan 2007, 11:25

by G200-GEM

thanks for taking the time to reply poida. i dont think the pressure regulator is setup incorrecty. the inlet (from the fuel pump) runs to the bottom of the canister, there is a vacuum line hooked up to the nipple on the top of the reg, and the outlet for the regulator is on the side which goes into the fuel rail.

all of the sensors were used on the car thlast time that it ran and i was told that it was running very smoothly. i have checked that the ECM is getting signal from all of the sensors using a multimeter and the wiring diagrams supplied. the setup came with a Camira 2L memcal and a twincam tuned one.

do you have any reccomendations on checking the flow rate and pressure of the pump? it was fro u-pull-it (self serve auto dismantlers) and therefore there was no guarantee of the condition of the pump. when pump fuel through the lines and to the location where the fuel pressure regulator should be, and put the hose in a bottle to catch the fuel, the flow is not steady, and it looks like it has air in the lines. so im not too certain of the condition of the pump at this stage. i think that i am going to get a new pump and relpace the pressure reulator or try the old one. to rule those two things out.

(I'm guessing that you have the G200W fuel rail and injectors with the 2 litre JE Camira EFI setup is that correct? ) that is right. it is the round type rail not the same as the 4Ze1 more like the piazza, but it uses the I-TEC plenum the same as the 4ze1 setup.

Posted: 20 Jan 2007, 09:49

by Poida

My twin cam is a G180W. It's a ZZ/R type. They run a different EFI system to the G200W engines.

I am looking to adapt a Delco to this twin cam engine because it's EFI system has a damaged air flow meter and besides, it's a fuel only system. There is no control of the ignition side at all. It still runs a set of points. Quite basic so I think I should be able to get more from it once it has better engine management.

Never in a hurry so it's just on hold for now. I have moved all my stuff from out in the weather into a factory which will allow me more undercover area to work on things so hopefully I can get some of the stagnant jobs on the go.

One thing about the EFI pumps is they are not supposed to be run dry. That kills them quick fast. I'd first do the checks to see that the pump is supplying correct pressure to the fuel rail. I would expect there to be some fuel passing out the return side of the regulator while the fuel pump is running. If there wasn't, it could be that the line pressure doesn't ever reach the regulator pressure level so the fuel rail pressure would be low as well as fluctuating. It's also important to make sure the pressure is correct for the injectors being used. Too high a pressure will cause bad spray patterns (and possibly leak past the valve) so don't be mislead into thinking a higher pressure system is better. If the pressure regulator is the original for that set of injectors then it shouldn't be a problem but if it is off some other engine it might be a missmatch.

Posted: 20 Jan 2007, 11:46

by G200-GEM

i got the car running with a new pump now and it starts and runs smooth. although any throttle and it slows then slowly picks up. its in limp home mode now and i have checked signal from sensors at the ECM etc. there is signal from all of the sensors and i know that the car was running before so i dont think that its an issue with incorrect sensors. i have taken the spark plugs out and the engine seems to be running lean??

Posted: 20 Jan 2007, 13:18

by G200-GEM

what causes the car to run in this limp home mode? this car is driving me nuts. it starts and runs occasionly backfires out the inlet, sometimes out the exhaust.

the throttle position sensor does not produce the input voltage the manual reccomends, its sitting at about .4v and its supposed to be .9v ? if i unplug it nothing changes, also the O2 sensor does nothing either.

taking one of the spark plugs or injector plugs changes it so all 4 are getting spark and injector spray, also the engine seems to run better when i advance the timing?

if i tap the dizzy cap the car almost dies. the rotor button has alot of plastic on it but has been broken off partially but should not effect it.

im about to fuckin shoot myself this engine is givin me the s#!ts lol

Posted: 20 Jan 2007, 19:48

by G200-GEM

Posted: 20 Jan 2007, 20:39

by G200-GEM

oh and i do have an issue with the timing it does not advance when the engine revs are increased. the previous owner (gembus) must have sorted it out but im not quite sure if anything was changed. im pretty sure this is the thing thats robbing me of power.

it may be something to do with the throttle position sensor because the variation i believe should be 0-5v but it only ranges from 0-2.8 or there abouts. i dont know if this would be an issue though?

also a couple of other sensors dont read the right voltage there not out by that much but they are out im not sure if its just not a great multimeter or if they are causing issues. i doubt it would matter too greatly.

i believe there was a way to reset the timing or something like that using the ADLD plug but i cant remember.

Posted: 21 Jan 2007, 00:50

by Poida

Because it's a "hybrid" with parts sourced from different cars you have to make sure everything is compatible with everything else. That's the first important step.

Limp home mode can be the result of any number of reasons. Generally it is caused by the range of a sensor being outside the expected readings. The Delco has an ability to fine tune using the 'block learning' memory. That allows the engine to adapt as components change in time yet still run efficiently. If one or more components is so far out of range that it can't adapt then it resorts to a state of open loop operation where only certain sensors are involved in management.

In limp mode the ignition timing is set to a programmed advance point (usually about 10°) and it doesn't alter with changes to engine speed and load. A limited number of sensors are used in limp mode and the rest are ignored.

STARTING MODE

When the ignition is turned ON the ECM energizes the fuel pump relay for two seconds, allowing the fuel pump to build up pressure. The PCM then checks the Engine Coolant temperature (ECT) sensor and the Throttle Position (TP) sensor. During cranking, the ECM checks the crankshaft position signal in order to determine the proper air/fuel ratio for starting. The ECM controls the amount of fuel delivered in the STARTING Mode by changing how long the fuel injectors are energized. This is done by pulsing the fuel injectors for very short times. The ignition timing is held at 10° crank advance (controlled totally by the ignition module) until the engine reaches the low RPM setting and then ignition control is managed by the ECU.

RUN MODE

The RUN Mode has two CONDITIONS called Open Loop and Closed Loop. When the engine is first started and engine speed is above the low setting RPM (generally between 400 RPM and the normal idle speed), the system is in Open Loop operation. In Open Loop the ECM ignores the signal from the Oxygen Sensor (O2S), and calculates the air/fuel ratio based on inputs from the TPS, ECT, MAP sensors. The system remains in Open Loop until the following conditions are met:

1. The O2S has a varying voltage output showing that it is hot enough to operate properly (this depends on temperature).

2. The ECT has reached a specific temperature (reported to be 170 degrees).

3. A specific amount of time has passed since starting the engine.

When these conditions are met, the system enters Closed Loop. In Closed Loop the ECM changes fuel injector on-time based on the signal from the HO2S. This allows the air/fuel ratio to stay very close to 14.7:1.

ACCELERATION MODE

The ECM provides extra fuel when it detects a rapid increase in throttle position and airflow.

There is a lot of good reading if you really want to learn about the Delco system. It can be adapted to run very efficiently in other non OEM applications. Don't be fooled into thinking it isn't capable of doing what all the top shelf aftermarket systems can do.

There is a limit to what you can do to a G series or a 4Z series engine. Some things like sequential injection are a bit beyond the scope of the average backyard tinkerer and batch firiing is easy enough to adapt to anything from a lawnmower to a V8 drag racer. Sequential injection is nice, in fact I'd be doing it if it was feasable, but it's not really much help to have a computer costing $1500 more that can control a sequential injection system, variable cam timing and the rest when the engine we are working with can't support that sort of technology. The humble Delco '808' is more than capable of doing the job in these sort of engines and the thing I like about them is they are well developed. GM has injected millions of dollars into getting it right. There have been mega millions of cars fitted with these systems and no aftermarket engine management system can even get near to that sort of sales figure or development capability.

Don't get me wrong, I am all for people trying out other types of management systems but I get annoyed when someone pops up telling everyone that Delco are shit and they advise the person/s to invest thousands in brand X which more or less does the same thing. So what if it supports sequential injection and variable valve timing too.... how useful is that to us? The good old (outdated in todays terms) batch firing system is what 99% of Gemini people will be looking at using. I haven't heard of anyone who has a sequential injection system or a variable cam timing engine in their Gemini yet. No doubt one day someone will fit in a late model engine that supports the above.

I support people who develop shareware systems and who offer the tinkerers a package that works, especially one that recycles easily found components and allows you to retune the ECM for ridiculously lower prices than the lowest priced aftermarket manufacturers. Apart from manipulating OEM gear, the only other system I'm even faintly interested in is the Megasquirt system because it's not an over the top money sponge. It's a low cost, well designed modular system that you can build on to suit your needs and it can be updated adding further components if the need arises further on down the line.

Posted: 21 Jan 2007, 00:58

by Poida

G200-GEM wrote:thanks heaps for the help ! the cars running fine now after fixing some wiring problems and adjusting the timing.

The ignition timing had issues because the distributor (astra dizzy i believe) because it hasnt been installed or 'converted' to well. it was actually running 10degrees retarded. i have set it to 10degrees advance and its running fairly well but could be a fair bit better. so its just tuning and some tinkering with things from here. im sure i will need some advice in the future!! be sure to keep me updated on any new info or discoveries with the delco poida!!!

Timing needs to be done after setting the engine into a controlled mode. You can do this by shorting two of the wires at the ALDL plug. It prevents the ECU from controlling the ignition timing (I'm assuming the system you have does in fact manipulate the spark timing) so you can set the dissy with a timing light. In most instances the static timing needs to be set at 10° BTDC.

G200-GEM wrote: the throttle position sensor does not produce the input voltage the manual reccomends, its sitting at about .4v and its supposed to be .9v ? if i unplug it nothing changes, also the O2 sensor does nothing either.

Just a word of warning about testing sensors etc., NEVER try to test the O2 sensor with a multimeter as the voltage it uses to check resistance will often fry the O2 sensor. There are some devices you can build to test and check that an O2 sensor is functioning properly. You can get these in kit form from Jaycar or I can direct you to a web site where they have developed easy to build kits to do lots of neat tests with delco ECU's.

Posted: 23 Jan 2007, 01:05

by G200-GEM

thanks. i agree with you on the system poida. it has limitations but not so much restrictions. i will use it untill i can get the cash together for one of WFCs kits. the main reason being that im more mechanically minded than electronically minded. and to be honest while its interesting i cant see the need for me to go so in depth with the delco system and go so far as to set up a system for tuning it when there is someone who has done all this, (like i assume you plan to do with the delco) with Megasquirt, which appears to have alot of good feedback also.

i copied this from the ozgemini thread that i starded so some of the personal references that i make probably make sense to you if you know what i mean.

thanks for the advice on the o2 sensor as well. it will be a valuable piece of information in the future.

EXTRACT FROM OTHER THREAD:

i have it sorted out the pressure reg was on the wrong side of the rail when i got the car. i made the mistake of being too anxious (AS I TEND TO DO ALMOST EVERY TIME

) to get it going and did not think things through properly. the car is running now but the maximum advance the dizzy will allow with the way he has set it up seems to be is 10degrees.

when i bridge A&B on the ALDL connector to set the timing to 10deg. the timing jumps back and retards to about 5degrees and i can not set it any different. i tried to set the dizzy to 10deg. but it would not allow it. 5deg. retarded was the most that it would allow for

i am certain that the dizzy is causing some of the major issues in the setup as the conversion done by the person who set the delco up is not the most professional job. i am going to rectify this and rig up something much more secure. at this stage i can tap the dizzy cap and the car will start to die off. its in no condition to be reliable or accurate..

okay Gemi coupe that is very valuable information. i am going to have to get the check light etc. from a camira as there is none installed. the ALDL connector is there and wired up correctly i checked with the wiring diagram.

the injectors are fine i have regularly checked the spark plugs and they are not fouled or too white, which indicates decent air/fuel mixtures. alot of the issues are with poor connections (half the metal clips on the sensor plugs are missing) and the dizzy. also there are some stupidly placed hoses with kinks in them which the cooling system is relying on. so i will replace them too.

the car is reasonable to drive now its got about the same power as a g161 maybe more but its evident that certain areas of the setup require more attention. ill try and post some pics up of the setup tomorrow. basically all of the Camira sensors have been adapted to the DOHC engine as not to confuse the ECM too much.

oh and the tps reads from .03v to 2.9v and the range is 0-5v so it should not be causing problems. i will know more when i get the check engine light in and working. at what time does this light flash? when the car is running or just when the ignition is on? and will it constantly run or do you need to trigger the diagnostic mode?

Posted: 23 Jan 2007, 21:21

by Poida

I was reluctant to offer a great deal of public assistance with the Delco info. Reason was I hadn't put a lot of what I've researched into practice so until I do some more hands on work I don't really think I can say I have the 'feel' for what I'm doing.

The last thing I want is to offer heaps of advice on how good the system is when I can't offer support to someone who goes ahead on my recommendation and builds a Delco managed engine then gets frustrated when it doesn't just fall into place like they hoped.

I am patient and have many cars so it doesn't phase me to have a car on hold for extended periods while I tinker with it. I've done heaps of research and I also have the specialist equipment to read, duplicate, modify, diagnose and write the programmed memory chips that are used in the memcal to control different engine packages.

I've been in communication with Warren (wfc) and he has offered his help in getting the plan up and going, in fact he has his own section of one of my other sites as a "project in construction" for the Megasquirt. He also has past experience and the knowledge that comes from that with the Delco system.

I've been in communication with the developers of the Kalmaker system sa well and they offered all the support that they could with the 'shareware' type system that I'm working with. Even though their setup is protected and a commercial product they are still interested in seeing this system working.

All in all I think it's a "bang for your bucks" way of setting up but I stress it's not a simple plug-n-play attachment that most people will be wanting. The kit that Warren assembles is more user friendly and his software is set up to run a Gemini straight out of the box.

One day, if I ever get the thing happening, I'd like to offer simple packages that will be suited for people just wanting to explore fitting EFI onto a more or less stock engine. I'm about to set up a bog stock TE auto sedam with such a setup. I need to adapt things like the puilse counter for the speed sensor and a suitable O2 sensor but most of the stuff will be sourced straight off Camira and Astra/Pulsar engines. It's about converting a car from a simple carburetor to an EFI system that runs smoother and offers better economy at the same time as a moderate torque and power gain.

It won't be what people who are expecting massive power increases straight out of the box are looking for BUT it will work as a basic experimenters package and the potential to modiy the engine for more power is there. All they need to do is invest the money to but the gear I have here and they can then do the same things to their system as they would be able to with any commercial type of EFI kit. I think if they want to get into that sort of setup then they should be learning all about it from the ground up. The most noticable thing though is that the Delco kit when fitted looks just like a factory fitted EFI setup and does not appear to be user programmable to the average person. Providing it's all fitted neatly as it would be in a factory fitted application, 999% of the cops would not realise it wasn't OEM whenf they looked at it.

As you should see from the links I offered you, there are some pretty in depth documents and programming packages already available on the open source scene for this Delco equipment.

Posted: 24 Jan 2007, 23:27

by G200-GEM

when i bridged the A and B on the diagnostics connector and take it for a bit of a drive (should i do this? ) and it runs quite well but i havent had a chance to rectify the dizzy, i still cant advance it enough.

That will force the engine to run in whatever the static setting is. The engine management cannot over ride that while in diagnostic mode. I don't think it will do any harm but it's sort of like being stuck in limp mode as well.

another thing that is interesting/annoying is that the car starts to s*#t itself when it gets up in temperature, and it goes into limp home mode.

You'll have to see if you can figure why that happens but it is probably due to one or meore info sources going out of the expected range after the engine gets warmed up. That might initiate a limp home mode status.

idle stepper motor does not appear to be installed i dont know what that is to be totally honest lol. ive only worked on carby motors untill this conversion.

The idle stepper is all that controls the idle settings. It adjusts constantly to keep the engine operating at a predetermined speed while it is on 0% throttle. NEVER adjust the idle by winding open the throttle butterfly so it begins to open the valce. The valve should be fully closed at idle and any air it needs is bled in by a special bleed passage. If you do screw the throttle valve open it throws the whole operation out of whack.

there is no speed sensor but the car does not have any issues with dropping off and stalling.

The engine management is programmed to expect a speed sensor reading and if it isn't there it can't operate correctly. Imagine the engine idles only because the throttle valve is screwed slightly open then the actual control device (the idle stepping motor) it's supposed to be opening or closing to set the speed but the computer can't manage that if it isn't connected. Also the reason you are finding it not stalling could be because the throttle valve is already open at the point it should be 0% open so once again the computer can't function correctly. that's two faulty devices as far as the computer is concerned. Add the incorrect TPS voltage and the O2 sensor out of range then that explains why the engine is not running right. Too many faults so I'd expect it to be staying in limp home mode. That may be why you can't set the timing as well. The sensors are keeping it forced in to limp mode so it remains theer when you disconnect the diagnostic link at the plug.

Too many things not right so until they are all accounted for you shouldn't be trying to tune it.

Suggestions, make sure the TPS is the same type as the one from the car which the memcal comes from. The same rule applies to the O2 sensorand the idle stepper motor. If you had hands on access to the programming gear you would be able to manually edit the data ranges to suit the non original sensors. In other words, if the resistance range of the TPS is calibrated differently to that on the memcal data, it won't ever be able to work if you had no way to reprogram the data.

Mixing components from different systems is only something you should do if you have the ability to alter the data.